We will introduce the process of a typical overhaul repair course.

*Depending on the model and condition of the piano, additions or changes may be made to the work details.

A piano is made up of many parts. We will dismantle it into pieces to make each task easier.

The frame of a piano that has been used for many years has become dirty with scratches, chips, dust, dirt, and rust.

After applying appropriate surface treatment, we can restore the item to a new-like condition by applying another coat of gold powder.

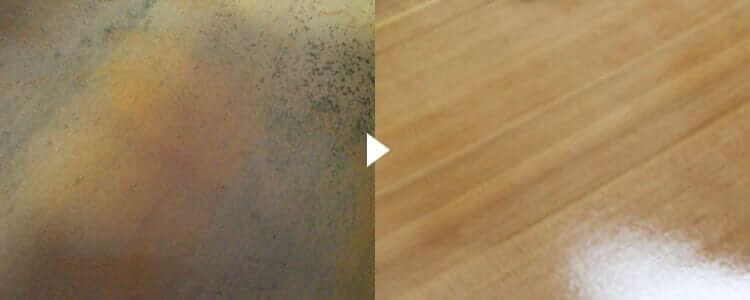

Due to long-term changes in temperature and humidity and the environment, the soundboard paint may crack, turn brown, or become sticky due to dirt and other particles.

After peeling off the paint on the soundboard that has deteriorated in this way and performing appropriate restoration work as necessary, it is carefully repainted in several stages with soundboard paint.

*When removing the frame, cracks in the bridge, cracks in the soundboard, or peeling of the soundbar may be discovered, but repairs will be required for a fee.

Along with painting the frame, the pin bushing will be replaced with a new one.

The tuning pins may be a little looser than when new due to the number of tunings, etc., so replace them with pins of an appropriate size and adjust the pin hardness (torque).

Also, by replacing the tuning pin with a new one, the rusted pin will regain its original shine.

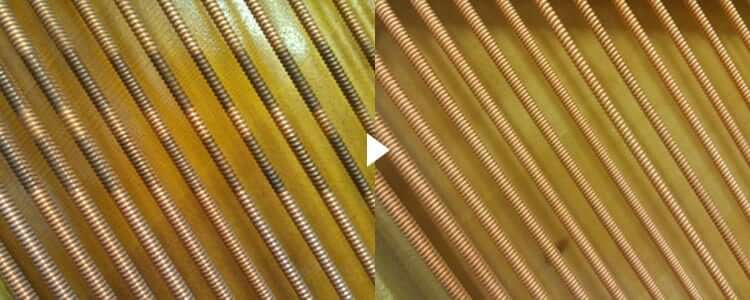

The winding is one of the areas where dirt can easily accumulate. When dust accumulates here, the dust attracts moisture, and the moisture causes rust, making it easier to generate noise (gin wire/bon wire).

Replacing it with a new winding will make it look nicer.

In order to make the string more beautiful and accurate, and to avoid damaging the frame, strings of a specific number are strung with a specific number of turns without twisting.

*Work details may vary depending on the condition of the piano’s exterior, the type of paint, etc.

The process below is an example of a typical repair.

As paints have improved and developed, various paints have been used in the world of pianos. Among the many paints, there are some that are not compatible with each other.

In that case, the original performance of the paint used can be maximized by removing the original paint.

Painting on a piano requires multiple layers of paint, and techniques are needed to spray the paint evenly even on complex shapes. Our skilled technicians, who have the knowledge of various paint combinations and the ability to spray evenly, create a durable, deep and beautiful paint job.

We use a belt sander to achieve smoothness and work speed that would be difficult to achieve with manual grinding.

The smooth sanded painted surface is polished step by step using several compounds and buffs.

The final result is a mirror-like reflection, as well as a richer color and deeper finish.

At our company, we achieve both speed and quality by using equipment suitable for each type, including large triple buffs, vertical buffs, and rotary buffs.

The most obvious change in a piano that has been used for many years is rust and discoloration of the metal.

By removing rust and polishing using a machine and polishing agent appropriate for the condition, dull metal parts can be restored to their original shine.

This is an important part related to the piano’s repeated playing performance. The tape often breaks due to insect damage or deterioration.

Replace it with a new one to restore the piano’s original functionality.

In general, if the string grooves become deep in the hammer felt due to frequent use, filing is the solution. If you repeat filing several times, the hammer will reach its usage limit and you will need to replace it.

If the hammer is misaligned, it may affect the volume and movement of the action,

If the position of the hammer is misaligned, it may affect the volume and movement of the action, so be careful about the striking point and angle.

If the damper of a used piano is severely deteriorated, it may be affected by moth damage, wear, etc.

The damper is an important part that stops the sound of a piano. Renewal will not only improve the appearance but also the usability during performance.

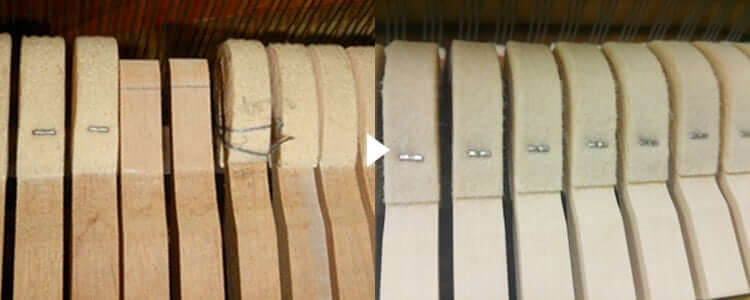

The interior of the piano is an area that is not often cared for, so years of dust and grime have accumulated on the wood of the action.

Since this is the vital part of a piano, we carefully remove dust and sandpaper any stains on the wood to keep it looking good.

Depending on the piano, the butt cord may break over the years.

If the bat cord breaks, the hammer will not return properly, making it difficult to hit repeatedly and affecting the touch, so replace it with one made of a material that is less likely to break.

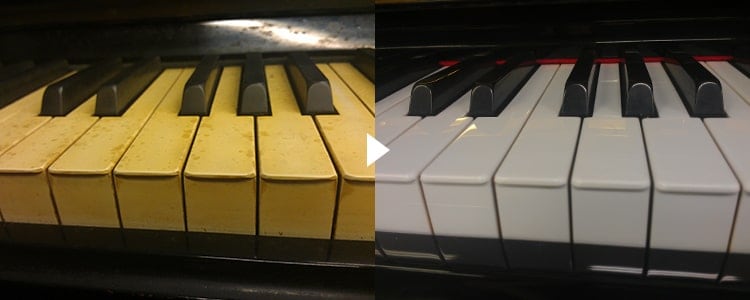

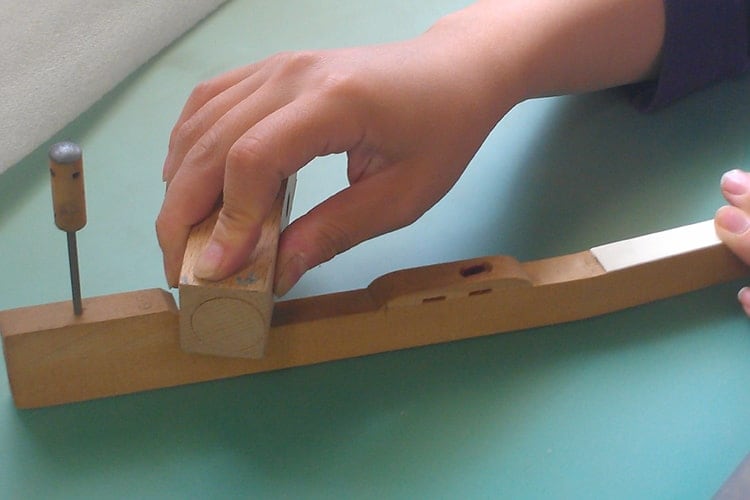

The keyboard parts on the piano are the most frequently touched parts. Of all the parts that make up a piano, this is the part that shows the most usability.

By replacing the top with a new one, you can return to a brand new, pure white keyboard with no scratches.

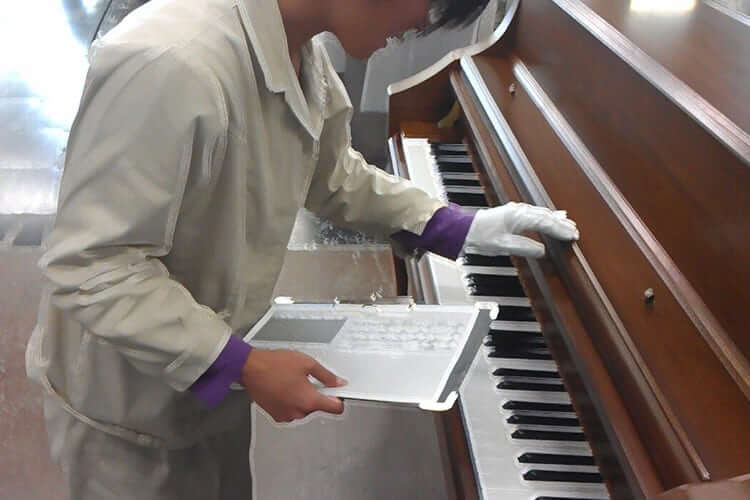

If the keyboard bushing cloth becomes worn due to frequency of use or the environment in which it is placed, or if it is eaten by insects, the keyboard may wobble more than necessary, making it uncomfortable to play, or making it difficult to adjust the action and keyboard. This will make it difficult to reflect.

Peel it off cleanly and replace it with a cloth of the appropriate thickness.

After many years of use, the wood inside the piano has accumulated more dirt than expected.

Remove dust and dirt from the keyboard using abrasive paper, etc.

By using a rotating buffing machine with an abrasive to further polish away slight scratches on the surface of the keyboard, a beautiful shine can be obtained.

The touch of the piano is brought out by aligning the internal mechanism of the piano to the dimensions appropriate for that piano.

Repeat seasoning – alignment several times, as new parts are prone to change until they get used to it.

Adjust the tension of the strings to adjust the pitch of each note one by one.

Newly stretched strings tend to stretch, so you may need to tune the string several times before it settles down.

Once the line process has been completed, the items stored in the warehouse undergo finishing adjustments again before being shipped.

The strings that have been tuned in the previous process are carefully tuned again before being shipped.

Here, we thoroughly check for any scratches or unpolished parts that may have occurred during the process, and then polish the item.

Flexible repair capabilities are required to respond to the depth of scratches and various phenomena, and the level of perfection is enhanced by skilled workers with years of experience and the ability to make appropriate judgments.

The inspector in charge will inspect the entire product and determine whether it is good or bad.

In the unlikely event that a defective repair is found, the work will be returned to the relevant worker and inspected again after the correction has been made.